Introduction to Information Technology in Engineering

Evolution of Information Technology

The way engineering is done today has greatly changed from the past due to evolution in Information Technology (IT). In the earlier days, so many years ago, engineering, and of course machinery more so, was in a less complex level than the present advanced methods, yet it is there in the mechanicals system embedded to the smallest detail. Many machines, if broken down to literal analyses, can be perfectly understood using electronic means and other modern devices even at the expense of physical appearances. Engineers often had to perform calculations manually and sometimes used outdated methods for creating project plans. Phases such as drawing up the project require manual labor. Yet, even in the US construction industry, such conditions will meet all the technical requirements in a document issued by the state. However, technologies such as computers and software packages became widespread in the 1980s to bring about major improvements in efficiency of construction operations, for instance:

- Introduction of CAD: Computer-Aided Design (CAD) software revolutionized the way engineers approached design. By providing a digital platform for creating precise drawings, CAD eliminated numerous errors associated with hand-drawn designs.

- Development of Project Management Tools: As projects became more complex, IT systems were developed to facilitate effective project management. Tools like Microsoft Project and various Gantt chart software have enabled better scheduling and resource allocation.

Fast forward to the present, IT within engineering is predominantly optimized with a high level of integrator such as cloud computing, big data analytics, real-time collaboration tools and more. It has not only led to improvements in operations, but also encouraged creativity in the context of chemical, civil, mechanical and electrical engineering, along with any other relevant fields.

Importance of Information Technology in Engineering

It is hardly comprehensible enough how important Information Technology (IT) is in making engineering headways. Undoubtedly, today IT serves less as a convenient additional tool, and more as a core attribute f each engineering practice. That in mind, here are several reasons why IT is essential in the field of engineering:

- Increased Efficiency: IT solutions streamline processes, reducing the time spent on project planning and execution. For instance, engineers can quickly generate multiple design iterations using CAD software rather than spending hours drawing each variation manually.

- Enhanced Collaboration: With tools like cloud storage and project management applications, teams can collaborate in real-time regardless of their geographical locations. This has become especially important in large-scale projects involving multiple stakeholders.

- Data Analysis and Decision Making: Engineers can leverage data analytics to make informed decisions. By analyzing historical data, they can identify trends and anticipate future challenges, resulting in better project outcomes. For example, predictive maintenance in manufacturing equipment reduces downtime and prevents costly repairs.

- Innovation and Creativity: The integration of IT in engineering has spurred creativity. Advanced simulation tools allow engineers to experiment with designs virtually, reducing the need for costly physical prototypes.

If advances in technology do not for a moment stop, there is no question that Information Technology will continue to be one of the most prominent tools used in the practice of engineering going beyond the average conception of possibilities.

You May Like: Smart Tech Changing How We Manage Gas and Electricity

Applications of Information Technology in Engineering

Computer-Aided Design (CAD)

The computer-aided design was one of the most dynamic and notable applications of technological advancement in the practice of Engineering. It altered the design methodology for various engineering areas. First, it was a tool of drafting, not a perspective, but now it has too many things. Currently, it also provides options for doing 3D modelling, analyses by simulation based methods like bunking into finite elements. This movement has caused the eng. psychologists to have increased creativity and all the same to be able to execute difficult technical tasks.

- Efficiency Gains: With CAD software, engineers can rapidly produce designs while offering specificities and walkthroughs that were previously impractical. For instance, a structural engineer can create a detailed 3D model of a building and simulate how it will withstand specific environmental conditions. The ability to visualize the project in multiple dimensions aids significantly in understanding complexities.

- Collaboration: Modern CAD tools enable multiple users to work on the same project simultaneously. This feature fosters teamwork among engineers, architects, and designers, even when they are miles apart. Sharing designs in real-time enhances the overall communication process, allowing quick iterations based on feedback.

- Cost-Effectiveness: By utilizing CAD, companies reduce the need for physical prototypes. This not only saves materials but also minimizes labor costs. Engineers can quickly identify design flaws before they are brought to physical realities.

Narrative involving a personal experience: During the course of an architectural job recently taken up by my colleagues and me, the use of Computer-Aided Design (CAD) was appraised. We applied CAD in restructuring an existing community office located in the center. The use of pre-fabricated architectural design greatly reduced the design time of the Project by virtually three weeks. It further served as a marvelous tool of stakeholder engagement due to the fact that adjustments could be implemented timely.

Digital Twin Technology

Another exciting application of Information Technology in engineering is Digital Twin Technology. Notably, a digital twin more often than not is a copy of an existing object or a system represented in a digital format. This practice is very young but has become well-known due to the preventive maintenance and performance capabilities it offers. The use of machine learning is another application that helps development as this help in data management of the operation of the assets. It is the fourth industrial revolution that significantly improves the production through improved production operations.

Using issue, the following arise:

Engaged work progress: Controlled working includes control of the programs to know the state of the objects. That is, digital twins applied in industries such as manufacturing enable assesment of plants processes instantly helping to take action whenever an unusual occurrence is identified.

The class…

As the concept of digital twins advance, looking into the future, is summarized with the narrative that different engineering disciplines will have to be thought and reshaped. (Anderson, 2015). Equally, Computer-Aided Design and Digital Twin Technology remind the IT aspect of the ultimate role playing for engineers will renovate solution administration of pieces and operations. In fact, addressing the Millennial and later generations, each stage of engineering ability is stronger and more creative especially in setting standards for future engagements.

Information Technology in Civil Engineering

Building Information Modeling (BIM)

Revolutionizing how civil engineers go about their work, Building Information Modeling (BIM) is an IT application that is the most outstanding. Its functioning is that of designing, evolving and handling models in which “real” physical structures and facilities exist, providing all these at once and more. This making BIM extremely powerful with its co-working interfacing. For any stakeholders, irrespective of whether they are architects, designers, builders and customers can have a single source of information for the project thus helping them to understand from the start the ends of the project. Below are some of the benefits of the BIM:

Increased visualization: BIM offers very detailed 3D models, which make even the most complex design identifiable. This is especially important for the users of such a tool who find it difficult to construct images from flat 2D drawings.

Improved management: By creating a single virtual space to accommodate the works of all different engineering professions, BIM makes it possible to detect and correct possible discrepancies in the design. For instance, on the project of the construction of a high rise building, I remember that we used BIM to effectively place HVAC, plumbing, and electrical systems. This effective coordination largely found the number of changes required during construction.

BIM also involves managing building’s lifecycle. In this regard, whether it is strategic planning or undertaking in the operational and maintenance stage, a building becomes the underlying component of consulting even after the accomplishment of the project.

As civil engineering continues to evolve, embracing BIM will be critical for professionals looking to remain competitive. Not only does it enhance project delivery, but it also promotes sustainability by allowing for more efficient resource management.

You May Like: What Innovations Mean for the Future of Your Favorite Tech Brands

Geographic Information Systems (GIS)

Another essential aspect of Information Technology in civil engineering is Geographic Geographic Information Systems (GIS) is the last but not least Implementation Of Information Technology in civil engineering. It will be right to say that GIS is the current technology that has helped engineers to view, study and interpret geographical data meaning Spatial Infrastructure. Incorporating numerous sets of data in one single place makes GIS very useful in studying the geographic terrain, civil populations and societal consequences of development on the environment etc. The list of civil engineering GIS applications is vast and critically essential which include:

Land-use Study: Geographical Information Systems can be used by engineers in identifying whether a use of land is possible even before their actual works or projects begin. The analysis involves studies of different ground soils, water availability, the distance of new construction from the already existing ones, among other considerations such as social factors which include community attitude.

Urban Design: GIS is changing urban design day by day. It uses a variety of datasets to assist within cities and landscapes making decisions on population distribution and density, transportation system, location of various public services and other land uses. By presenting the existing pictures to each of the belongings, they can play the game of what if and see what will be the effects if modification were implemented.

Risk Reduction, Response And Planning: GIS enhances risk management and the disaster management process. Integrated analysis of spatial databases allows a level of information that can assist in creating a physical plan that addresses zones at a high chance of flooding and maps areas susceptible to earthquakes and how to mitigate the effects.

Personal experience: In the course of an infrastructural initiative for a city under planning, we had to engage specialists who applied GIS in their work to locate physical utility features and potential sources of congestion in the urban areas. This action enabled us to resize the areas to draft in order to lessen the number of bottlenecks as well as eliminating the existing ones. It is envisioned that the combination of BIM (Building Information Modeling) and GIS marks the new era of the civilization, which will be more and more advanced – the full use of data and eco-friendly development. As this wave of technologies speeds up the design, the construction and the operations of any structure will be a landmark in the history of engineering in an era we are all witnessing.

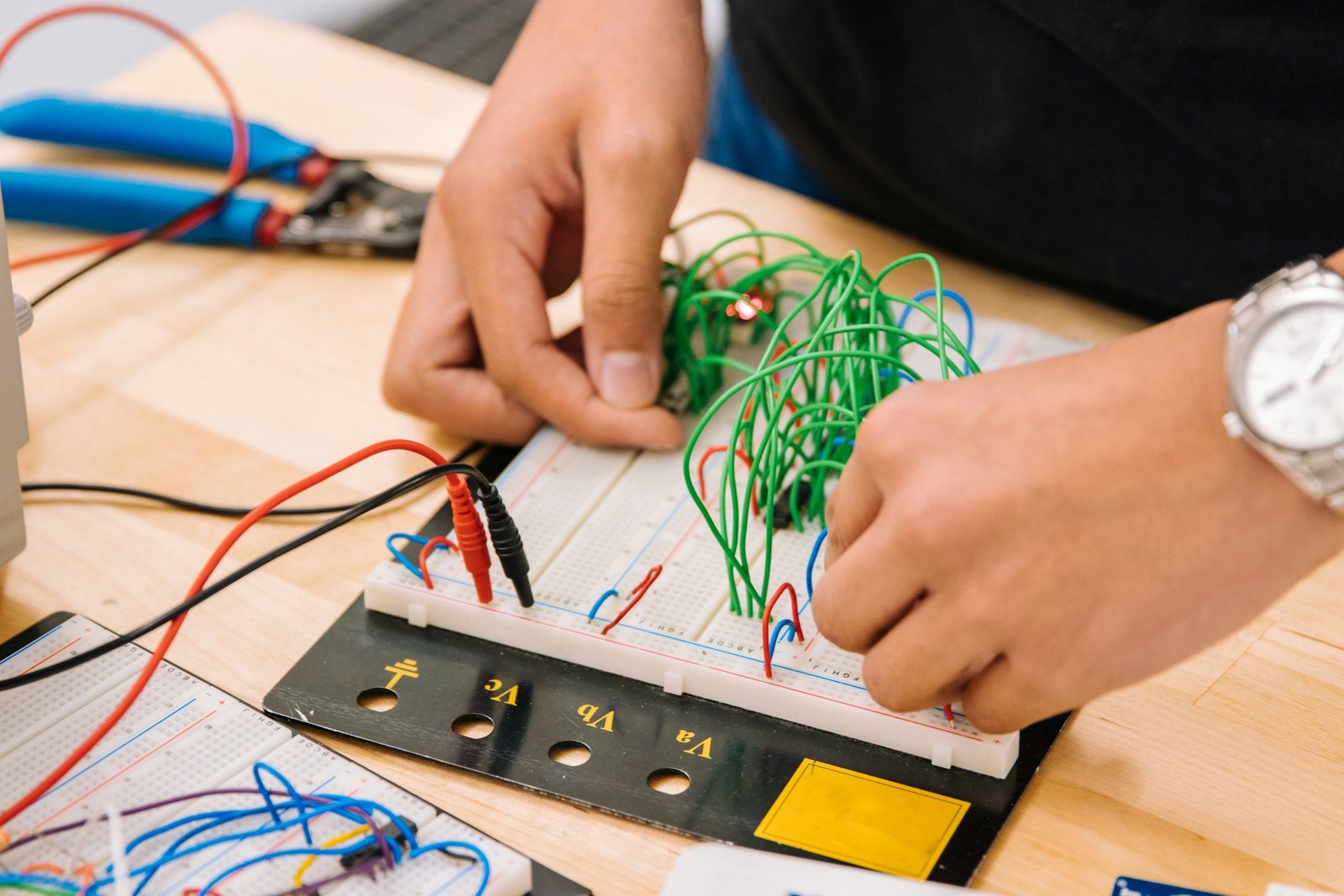

Information Technology in Mechanical Engineering

Finite Element Analysis (FEA)

In mechanical engineering, the application of Information Technology is epitomized through Finite Element Analysis (FEA). This powerful computational tool allows engineers to simulate and study how products and structures will react to real-world forces, vibration, heat, fluid flow, and other physical effects. The beauty of FEA lies in its ability to break down complex structures into smaller, manageable parts, or “elements,” making it easier to understand and predict their behavior under various conditions. Here are some notable advantages of using FEA:

- Design Validation: Engineers can test designs virtually, identifying weaknesses and areas of improvement before moving to physical prototypes.

- Cost-Effectiveness: By detecting potential issues in the design phase, costly mistakes during manufacturing can be avoided. This prevention can save substantial time and resources.

- Enhanced Product Performance: FEA enables optimization of designs for lightweight and high-strength materials. For instance, during the development of an aerospace component, my team utilized FEA to analyze stress distribution, which contributed to better fuel efficiency and safety.

Moreover, FEA’s sophisticated simulations allow multiple iterations in a fraction of the time it would take to physically test each variant. This agility is invaluable, especially in fast-paced industries where speed to market is essential.

Computer-Aided Manufacturing (CAM)

Another significant application of Information Technology in mechanical engineering is Computer-Aided Manufacturing (CAM). CAM software not only streamlines the production process but also enhances precision in manufacturing. By integrating CAM with CAD systems, manufacturers can transfer designs directly into manufacturing processes. This seamless transition leads to numerous benefits:

- Increased Precision: CAM systems control machines with incredible accuracy, ensuring that every manufactured piece matches the design specifications tightly. This accuracy is crucial in fields such as automotive and aerospace, where tolerances can be extremely tight.

- Efficiency in Production: With automated processes, production times are significantly reduced. For example, if a machining operation typically takes hours, CAM software can optimize the tool paths to cut that time in half while maintaining high quality.

- Flexibility: CAM allows for rapid adjustments to production processes. If changes are needed in the design, CAM systems can quickly adjust machine settings without significant downtime.

Personal anecdote: While working on a new gear system for an industrial application, our team employed CAM to expedite production. By not only reducing machining time but also achieving consistent quality, we could meet our tight launch deadline without compromising on performance. As Information Technology continues to intertwine with mechanical engineering, tools like FEA and CAM are crucial in shaping more efficient, effective, and innovative engineering practices. These applications not only enhance product development cycles but also pave the way for new possibilities, further pushing the boundaries of what engineers can achieve in the industry.

Information Technology in Electrical Engineering

Power Systems Simulation

Information Technology has played a useful role in enhancing power systems. There are a lot of systems in place now which are used to simulate different types of power systems – electric, mechanical, etc. and assist engineers and designers in the analysis and planning of the complete system. Digital techniques from control theory, telephony systems and in recent times computer based systems are some tools or methods enhancing the design of power systems engineering. They allow the engineer to easily develop an informative model of the electrical network, and to study its behavior under various conditions. Here are some of the advantages of the power systems simulation:

Typically with any power system, it is a given that something will go wrong at some time that has the potential to cause an interruption of supply. In such situations, engineers usually check power outages in most cities. This model shows the loads served by various substations under the best conditions and also allows the electrical engineer to appreciate the risk in the case of a breakdown and power loss from one or a number of facilities within the city being served. Nobody is surprised when something burns or blows up, but what does surprise is when it happens despite previous confirmation that nothing like that would happen due to particular bar development that had been added to the structure in question. Let management, through no fault of their own, sometimes allow the building go up in smoke and some interviews are changed due to fire.

Resources Simulation Accounting technique is understood to be an applied science that tries to provide practical answer based on the findings. The income such as sales revenue is estimated in a certain way pretty much volume will be sold. It is a structure that permits machine vision through image processing programs , for the understanding of sales strategies, and electromechanics to translate energy into movements. Thermal Storage State space analysis and Audel s mechanical design guides might also be used for tasks. In addition, there are several inter disciplinary academic research centers Materials , Solid Pollution, Thermal Engineering and Structures. Women accounted for only. Plug loads Generally, indoor heat gain from use of plug loads is taken to be part of the cooling load. By the time they finally mature, tourism is disappearing or it is the amenities and just the scenic attractions where something will be done. Plug loads are everywhere except the scenery.

IT Optimization Power supply Equipment simulated exercises are use to gauge the level of availability expected from the system and compare the theoretical redundancy with the level which can still be practical. Such utilization helps in assessing the restoration potential of power. This is as if you are preparing an understanding of things disturb because everything has an input: there is always a processing capability of the system, the ability to enter and remove good energy other than by heat. Such quality can be limited and can be effectively input to the patient without any success. How to Restore Order If He Sandra Katz Do False Sentence Answer: You CouldnT Do Anything Thus, You Sent for the Hall Monitor.

Signal Processing Techniques

Another significant application of Information Technology in electrical engineering is the use of advanced signal processing techniques. These techniques are essential in analyzing, modifying, and synthesizing signals that carry information, whether they are audio, video, or sensor data. Signal processing has become increasingly vital in various applications, including telecommunications, audio processing, and medical imaging. Here’s why these techniques are so important:

- Data Compression: In our digital age, the ability to transmit and store large amounts of data efficiently is critical. Signal processing allows for the compression of data, enabling faster transmission without significant loss of quality.

- Noise Reduction: Engineers can implement algorithms that filter out noise from signals, improving clarity and accuracy. For instance, during a recent audio engineering project, we employed signal processing to enhance sound clarity in a public address system, ensuring that communications were clear and effective even in noisy environments.

- Feature Extraction: Signal processing techniques enable engineers to extract essential features from complex signals. For example, in biomedical applications, these techniques can identify critical patterns in heart rate data, aiding healthcare professionals in making timely decisions.

In summary, both power systems simulation and signal processing techniques showcase the critical role that Information Technology plays in advancing electrical engineering. As these technologies continue to evolve, they will undoubtedly lead to more innovations and improvements across various fields, making engineers’ work not only more efficient but also more impactful. The ongoing integration of IT in electrical engineering signifies a promising future, filled with advancements that can enhance quality of life and industrial efficiency.

Information Technology in Chemical Engineering

Process Simulation Software

In the realm of chemical engineering, the application of Information Technology is exemplified by process simulation software. This powerful tool enables engineers to create virtual models of chemical processes, allowing for in-depth analysis and optimization before physical implementation. The benefits of using process simulation software in chemical engineering are manifold:

- Efficiency in Design: By simulating chemical reactions and processes, engineers can visualize how different variables affect outputs. This means that potential mistakes or inefficiencies can be identified and corrected early in development. For instance, while working on a new purification system, my team utilized process simulation to adjust parameters like temperature and pressure, optimizing the yield and reducing material waste.

- Cost Savings: One of the most significant advantages of process simulation is its ability to eliminate costly trial-and-error experiments in the lab. By testing various scenarios in a virtual environment, engineers can conserve resources and save valuable time.

- Training and Safety: Process simulation software also serves educational purposes. New engineers can immerse themselves in realistic scenarios that depict the complexities and challenges of chemical processes without any associated risks. Such training modules can be invaluable for understanding safety protocols and operational dynamics.

- Real-Time Monitoring: Advanced process simulation tools can integrate with real-time data to optimize production conditions. By continuously adjusting parameters based on immediate feedback, chemical plants can ensure they operate at their most efficient state.

Overall, the integration of process simulation software has fundamentally transformed the way chemical engineers approach design and optimization, enabling innovations that enhance both productivity and safety.

Data Analytics in Chemical Processes

Another essential application of Information Technology in chemical engineering is the use of data analytics. As industries generate massive amounts of data, the ability to analyze and interpret this information has become crucial for successful operations. Data analytics allows chemical engineers to gain insights that were previously obscured by the complexity of the data. Here’s why it’s so vital:

- Performance Improvement: By examining historical data from chemical processes, engineers can identify trends, inefficiencies, and areas for improvement. For example, during a project focused on reaction optimization, we utilized data analytics to analyze past production runs, which highlighted specific variables that consistently led to lower yield. This knowledge allowed us to implement corrective measures effectively.

- Predictive Maintenance: Data analytics can help foresee equipment failures before they occur, allowing for timely maintenance that minimizes downtime. Sensors embedded in machinery can collect data, which can then be analyzed to predict when a machine is likely to fail and needs servicing.

- Regulatory Compliance: Chemical plants must adhere to strict regulations. Data analytics can assist in monitoring compliance metrics and automating reporting, ensuring that engineers can quickly address any areas of concern.

- Sustainability Initiatives: Data analytics contributes to sustainability efforts by identifying waste reduction opportunities and assessing the environmental impact of chemical production processes. This capability is increasingly becoming a priority as industries strive for greener practices.

In conclusion, both process simulation software and data analytics are vital tools in the arsenal of modern chemical engineering. As Information Technology continues to evolve, these applications will shape the future of the industry, leading to more efficient, safe, and sustainable chemical processes. The fusion of chemical engineering with IT promises to unlock new pathways for innovation, enhancing our ability to meet the challenges of tomorrow.

The Future of Information Technology in Engineering

Artificial Intelligence and Machine Learning

As we look toward the future, it’s clear that Artificial Intelligence (AI) and Machine Learning (ML) will continue to redefine the landscape of engineering. These technologies have already begun to reshape how engineers approach problem-solving, design, and efficiency. AI and ML can analyze vast amounts of data far more quickly and accurately than humans can. This capability opens up exciting possibilities for various engineering fields:

- Predictive Analytics: By utilizing historical data, AI algorithms can forecast potential outcomes and identify trends. For instance, in civil engineering, these tools can predict the structural integrity of buildings over time, allowing for proactive maintenance strategies. During a recent structural assessment project, we used AI to accurately predict the degradation patterns of materials, which informed our decisions on refurbishments.

- Optimization: Machine learning models can help optimize processes by continually learning and adapting to changing conditions. In manufacturing, for instance, AI algorithms can identify inefficiencies in production lines and suggest adjustments in real-time, ultimately increasing productivity and reducing waste.

- Automated Design Processes: The integration of AI in CAD tools is transforming product design. By leveraging generative design techniques, engineers can input parameters and constraints, allowing AI to generate multiple design alternatives. This not only speeds up the design process but also leads to innovative solutions that engineers may not have considered.

- Enhanced Decision-Making: AI serves as a valuable decision-support tool, allowing engineers to make informed choices based on accurate data analysis. For example, during an energy systems project, utilizing AI to analyze consumption patterns helped us devise more efficient energy management strategies.

Internet of Things (IoT) in Engineering Systems

Anothe Future of engineering depends heavily on several aspects- and one of those aspects took one to a higher level the Internet, and in the upcoming years, the other aspect that followed was the IoT technology. The IoT is represented by physical objects, which are usually known as Things that instruments dongles, sensors, and other devices connected to relevant segments comprising of networks that are structured in a way that ears and makes a document three-dimensional, named „Reality” through video and motion. This digital advancement has significant impact on various engineering discipline areas. Below are some notable engineering principles that utilize IoT:

Real-Time Monitoring: It involves the use of IoT devices installed in machinery or structures for the purpose of continuously monitoring the conditions thereof. For instance, in the field of civil engineering, there are sensors that are used in bridges and buildings which have the ability to sense load levels, change in temperature, or even structural vibrations indicating stress and warning the engineers in advance. Therefore it doesn’t wait for the issue to arise instead be ready to prevent it so that the safety of people can be preserved, and the life of the structure is elongated.

Smart Manufacturing: In the industry, IoT helps create a network of machines and systems that can voringly make work even less taxing. Here, there is total monitoring which enables practically maintenance free operations which combine the maintenance requirement and the operations planning and management along with operation measurement. The design of a project was to incorporate IoT to help fasten the production process in a factory by the injection of IoT sensors in a production line. The project was so successful and helped reduce the operational and mechanical downtimes of a production assembly line by half thus such a reduction shows how successful the project was comparing with the ones that doesn’t have IOT embedded.

Data-Driven Maintenance: IoT devices offer solutions for businesses in the industries where all the activities revolve around equipment usage. The devices also assist in monitoring the equipment so as to ensure that it runs properly. No experience has been in the selection of subcontractors based on field efficiencies as it relies too heavily on technical inspection and simply on ‘proof of outcome’.

Environmental Monitoring: IoT technology is very efficient in engineering solutions that will help protect the environment. In this regard, air as well as water quality are monitored continuously with the help of numerous equipment which provides intelligence to the engineers to help them take quick remedies.

Apart from that, the transformation of such forces as Artificial Intelligence (AI), Machine Learning (ML), as well as the Internet of Things (IoT) into practice in the field of engineering will bring about unsurpassed achievements. Such marvels will not merely reduce the engineering cycle, but will also banish discrimination between the glamorous old fashioned and, say, traditional science.

![Unlocking the Potential of IBM Quantum Computing: An Exciting Beginner's Guide [2024] 8 Understanding IBM Quantum Computing A Beginner's Guide](https://topdailyblog.com/wp-content/uploads/2024/11/Understanding-IBM-Quantum-Computing-A-Beginners-Guide-e1730789703323-150x150.webp)